Some Main Products

BALL MILL 球磨机

The mineral processing ball mill is core equipment in the mining separation and screening field, primarily applied in metallurgical and chemical mining industries, as well as the building materials processing sector.”

Types of Ball Mills

1.Rolling bearing ball mill Product Features:

1) Uses rolling bearings as the main transmission structure.

2) Both ends are supported by double-row spherical roller bearings for shaft rotation; the hollow shaft diameter acts on the bearings, resulting in low friction and easy lubrication and maintenance.

3) Can effectively reduce the energy consumption of the ball mill.

2.Hybrid bearing wet type ball mill Product Features:

1) Uses hybrid bearings and a high-pressure oil pump during start-up and shutdown to reduce starting load and breakaway starting current. 2) Equipped with an air clutch; starts in sections to reduce the motor’s starting load and the impact on large and small gears, avoiding gear breakage.

3) Can be customized according to customer requirements: a. A hoisting device for equipment disassembly, overhaul, and lifting the barrel during long-term shutdown. b. A lubrication device for self-lubrication of the transmission device, which lengthens the service life of large and small gears, reduces lubrication costs, and has reliable performance. c. A low-speed device for slow rotation, loosening materials, and dismantling the liner.

3.Vonical millChinese Patent,

International Silver Medal Patent Number: 88219890.4

The mill weight is reduced by 30-50%, power consumption is saved by 30-60%, the grinding particle size (-0.074mm) is increased by 10-20%, and noise is reduced by 5-10 decibels.

FLOTATION MACHINE 浮选机

Flotation Machine

(The term “flotation machine” is short for froth flotation machine, referring to the mechanical equipment that completes the flotation process.)

In the flotation machine, the pulp treated with chemical reagents undergoes agitation and aeration. This causes selected mineral particles to attach to air bubbles, which rise to the surface of the pulp. The mineral-laden froth is then scraped off to form a concentrate product. The remaining material stays in the pulp, achieving mineral separation.

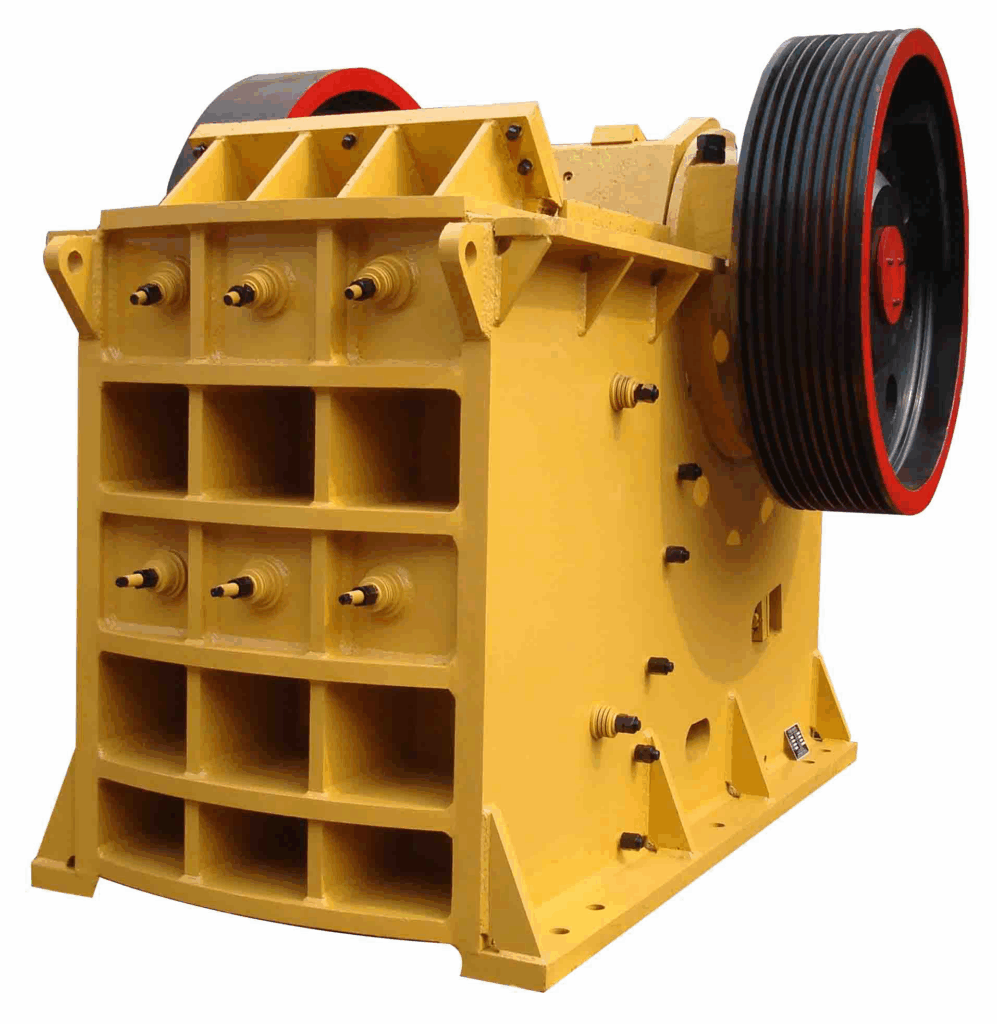

PEseries JAW CRUSHER

P系列颚式破碎机

Jaw Crusher Translation: Jaw crushers are primarily used as primary and secondary crushers in mining, building materials, and infrastructure construction sectors. They are categorized into three types based on feed opening size: large, medium, and small. Machines with a feed opening greater than 600 mm are classified as large-scale; those with openings between 300 mm and 600 mm are medium-sized; and crushers with openings smaller than 300 mm are small-scale units. The jaw crusher features a simple structure, ease of manufacturing, and reliable operation.

Screening Equipment

筛分设备

Mining vibrating screen is an industrial screening equipment powered by vibration motors or exciters, employing rubber spring damping technology. It is widely used in the metallurgical, mining, and coal industries.

Key Advantages:

Efficient Screening: Adjustable excitation force (via adjusting eccentric block counterweight) adapts to minerals of different densities and humidities, with a screening efficiency of over 85%.

Multi-layer Classification: Configurable with 1-5 layers of screens, completing separation of 2-6 particle size grades in one pass (e.g., 0.5-1mm, 1-3mm, etc.), meeting the needs of multi-stage mineral processing flows.|

Strong Durability: Sieve frames are made of high-strength steel; screens can be made of manganese steel, polyurethane, or stainless steel, featuring wear resistance and impact resistance, suitable for harsh mineral screening environments.

Easy Operation: Compact structure, simple to install and maintain; can be linked with crushing and ball milling equipment, and supports automatic control (such as remote monitoring of vibration frequency and amplitude).

Applicable Scenarios: Coarse/fine screening of metal ores, classification of sand and gravel aggregates, dehydration and desliming of minerals, tailings recovery, etc. It is a key equipment to improve mineral processing efficiency.

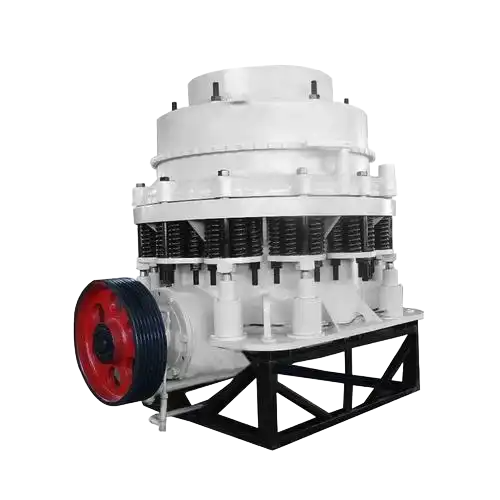

CONE CRUSHER 圆锥破碎机

The core equipment for efficiently crushing hard rockThe cone crusher is the “main model” in the field of mining crushing. It crushes materials through the periodic compression and bending action between the moving cone and the fixed cone, suitable for medium or fine crushing of high-hardness ores (such as gold ore, copper ore, iron ore, etc.). It features high crushing efficiency, uniform product size, and low energy consumption. Its core structure includes the frame, moving cone, fixed cone, eccentric shaft sleeve, and so on. By adjusting the gap between the moving cone and the fixed cone, the discharge particle size can be controlled (usually between 5-50mm).